Introduction to Supply Chain Automation and Integration

In an era where efficiency and speed are paramount, understanding the latest trends in supply chain automation and integration has become crucial for businesses across the globe. This domain has evolved from mere logistical coordination to a sophisticated network of automated and integrated solutions, shaping the backbone of successful enterprises.

Why Focus on the Latest Trends in Supply Chain Automation and Integration?

The landscape of supply chains is rapidly changing, influenced by technological advancements and shifting market demands. In this context, staying abreast of the latest trends in supply chain automation and integration is not just beneficial. It’s essential for maintaining competitiveness and agility. From enhancing operational efficiency to reducing costs and improving customer satisfaction, these trends offer a myriad of benefits.

The Evolution of Supply Chain Management

Historically, supply chain management focused on optimizing individual elements of the supply chain. However, with the advent of new technologies and the integration of advanced systems, the focus has shifted towards creating a more cohesive and responsive ecosystem. The latest trends in supply chain automation and integration now emphasize real-time data analysis, predictive modelling, and seamless connectivity across various supply chain components.

A Glimpse into the Future

As we delve deeper into this blog post, we will explore how artificial intelligence, machine learning, blockchain, the Internet of Things (IoT), and other innovations are driving the latest trends in supply chain automation and integration. Each of these technologies plays a pivotal role in transforming traditional supply chain models into more efficient, transparent, and resilient systems.

In conclusion, the latest trends in supply chain automation and integration are not just reshaping how businesses manage their supply chains; they are redefining the very nature of global trade and commerce. By understanding and leveraging these trends, companies can unlock new levels of efficiency and innovation, setting the stage for sustained success in an increasingly complex and dynamic marketplace.

The Rise of Artificial Intelligence and Machine Learning

One of the most significant latest trends in supply chain automation and integration is the integration of Artificial Intelligence (AI) and Machine Learning (ML). These technologies are revolutionizing the way supply chains operate, from forecasting demand to optimizing logistics.

AI and ML in Demand Forecasting

Accurate demand forecasting is crucial for supply chain efficiency. AI and ML algorithms can analyze vast datasets, including historical sales data, market trends, and even weather patterns, to predict future demand more accurately. This enhanced forecasting ability is a pivotal aspect of the latest trends in supply chain automation and integration, allowing businesses to optimize their inventory levels and reduce waste.

Automated Inventory Management

AI-driven inventory management systems are another key element of the latest trends in supply chain automation and integration. These systems can automatically track stock levels, predict when replenishment is needed, and even initiate purchase orders. This automation not only saves time but also significantly reduces the risk of human error.

Real-time Analytics and Decision Making

Real-time analytics powered by AI and ML are transforming decision-making processes in supply chains. By analyzing data as it’s generated, businesses can make informed decisions quickly. This capability is essential in today’s fast-paced market and is a core component of the latest trends in supply chain automation and integration. It enables companies to respond proactively to unexpected changes in demand or supply chain disruptions.

In summary, the rise of AI and ML is a game-changer in the world of supply chain management. As part of the latest trends in supply chain automation and integration, these technologies are not only enhancing efficiency but are also paving the way for more agile, responsive, and intelligent supply chain systems. The subsequent sections will further explore how other technologies like blockchain and IoT are also contributing to these transformative trends.

Blockchain Technology for Enhanced Transparency

Blockchain technology is emerging as a cornerstone in the latest trends in supply chain automation and integration, offering unprecedented levels of transparency and security. This technology is particularly transformative in how supply chains track and verify the authenticity of products and transactions.

Blockchain in Tracking and Verification

In the realm of the latest trends in supply chain automation and integration, blockchain stands out for its ability to create an immutable ledger of transactions. This feature is invaluable in supply chains, where tracking the origin, journey, and authenticity of products is crucial. Blockchain enables all parties in the supply chain to access a single source of truth, ensuring transparency and trust in the process.

Improving Supplier and Partner Relationships

Blockchain technology is also instrumental in enhancing relationships between suppliers and partners. By providing a transparent and tamper-proof record of transactions and agreements, blockchain reduces disputes and builds trust. This aspect of the latest trends in supply chain automation and integration helps in creating more collaborative and efficient supply chain networks.

Blockchain and Cybersecurity in the Supply Chain

Cybersecurity is a growing concern in supply chain management. Blockchain’s inherent security features, such as decentralized storage and cryptographic encryption, make it an essential component of supply chain automation and integration. By safeguarding data and transactions, blockchain technology significantly reduces the risk of cyber-attacks and data breaches.

In conclusion, blockchain technology is not just a trend; it’s a transformative force in supply chain automation and integration. Its ability to ensure transparency, enhance trust among stakeholders, and provide robust security measures positions it as a key player in shaping the future of supply chain management. The upcoming sections will delve into how other technologies like IoT and advanced analytics further contribute to these evolving trends.

Omnitas Newsletter

Sign up for our monthly newsletter to stay up-to-date on our latest blog articles, videos and events!

Thank you!

You have successfully joined our subscriber list.

Internet of Things (IoT) Revolutionizing Supply Chain Operations

The Internet of Things (IoT) is a pivotal force in the latest trends in supply chain automation and integration. By connecting physical objects to the internet, IoT technology is enabling smarter, more efficient supply chain operations.

IoT for Real-time Tracking and Monitoring

A critical aspect of the latest trends in supply chain automation and integration is the ability to track and monitor assets in real-time. IoT devices such as GPS trackers and RFID tags provide continuous visibility into the location and condition of products throughout the supply chain. This real-time data is invaluable for optimizing routes, reducing delays, and ensuring the integrity of sensitive or perishable goods.

Predictive Maintenance with IoT Devices

IoT technology is also transforming equipment maintenance in supply chains. By equipping machinery and vehicles with IoT sensors, companies can monitor their condition and performance in real-time. This allows for predictive maintenance, where potential issues are addressed before they lead to breakdowns or disruptions. Embracing this trend in supply chain automation and integration not only enhances operational reliability but also saves costs associated with unplanned downtime.

Enhanced Customer Experience through IoT Integration

Integrating IoT into supply chain systems plays a significant role in improving customer experiences. By providing customers with real-time updates on their orders and enabling more accurate delivery predictions, IoT technology helps businesses meet and exceed customer expectations. This level of service is becoming increasingly important in today’s competitive market.

In conclusion, the Internet of Things is revolutionizing supply chain operations, making them more transparent, efficient, and customer-focused. As part of the latest trends in supply chain automation and integration, IoT is not just a technological upgrade; it’s a fundamental shift towards more connected, responsive, and intelligent supply chains.

The Impact of Robotics and Automation

Robotics and automation represent a crucial evolution in the latest trends in supply chain automation and integration. These technologies are redefining efficiency and precision in various aspects of the supply chain.

Robotics in Warehousing and Logistics

In the sphere of warehousing and logistics, robotics is a game-changer. Automated guided vehicles (AGVs), robotic arms, and sorting systems are now common in modern warehouses. These robotic systems increase throughput, reduce errors, and can operate around the clock, significantly enhancing operational efficiency.

Drones in Delivery and Inventory Management

Drones are another exciting aspect of the latest trends in supply chain automation and integration. They are being increasingly used for quick and efficient delivery, especially in remote or difficult-to-access areas. In inventory management, drones equipped with scanners can swiftly and accurately track stock levels in large warehouses, a task that would be time-consuming and error-prone if done manually.

Collaborative Robots (Cobots) in Manufacturing

The introduction of collaborative robots, or cobots, in manufacturing settings, is a testament to the evolving trends in supply chain automation and integration. Cobots are designed to work alongside human workers, enhancing their capabilities rather than replacing them. They contribute to safer, more ergonomic work environments and can be easily reprogrammed for different tasks, bringing flexibility and efficiency to manufacturing processes.

In summary, the integration of robotics and automation technologies is significantly impacting supply chain operations. As part of the latest trends in supply chain automation and integration, they are not only streamlining processes and reducing costs but also opening up new possibilities for innovation and improved service delivery.

The Role of Cloud Computing in Supply Chain Integration

Cloud computing has emerged as a fundamental component in the latest trends in supply chain automation and integration. Its role in enhancing connectivity, scalability, and collaboration cannot be overstated.

Scalability and Flexibility with Cloud-based Solutions

One of the key advantages of cloud computing is its scalability. Businesses can easily adjust their cloud services according to their current needs, ensuring they are not paying for unused resources. This flexibility is crucial in managing the dynamic demands of modern supply chains, allowing for rapid scaling up or down in response to market changes.

Improved Collaboration and Data Sharing

Cloud computing facilitates seamless collaboration and data sharing across the supply chain. By providing a centralized platform accessible from anywhere in the world, cloud solutions break down silos between departments, suppliers, and customers. This integration leads to improved decision-making, enhanced transparency, and more synchronized operations.

Cloud Computing and Disaster Recovery

Another critical aspect of cloud computing in supply chain integration is its contribution to disaster recovery. Cloud-based systems offer robust backup and recovery solutions, ensuring that supply chain operations can quickly resume in the event of system failures, cyber-attacks, or natural disasters. This resilience is increasingly important and is a vital part of the latest trends in supply chain automation and integration.

In conclusion, cloud computing is not just a technological tool; it’s a strategic asset. It enables businesses to be more agile, collaborative, and resilient, which are essential qualities in today’s fast-paced and interconnected world.

Advanced Analytics for Better Decision-Making

Advanced analytics is a key driver in the latest trends in supply chain automation and integration, offering deeper insights and improved decision-making capabilities for businesses.

Big Data in Supply Chain Optimization

The integration of big data analytics into supply chains represents a significant shift in supply chain automation and integration. By analyzing large volumes of data from various sources, businesses can gain comprehensive insights into their supply chain operations. This deep understanding enables more informed decisions, leading to optimized processes, reduced costs, and enhanced customer satisfaction.

Predictive Analytics for Risk Management

Another critical aspect of advanced analytics in the context of the latest trends in supply chain automation and integration is predictive analytics. This technology helps businesses anticipate potential disruptions and vulnerabilities in their supply chain. By predicting these challenges before they occur, companies can proactively implement strategies to mitigate risks, ensuring smoother and more reliable operations.

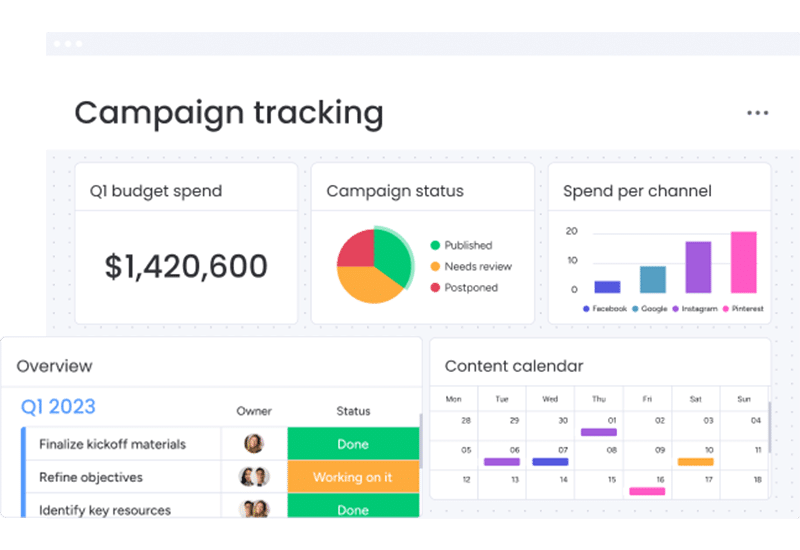

Visual Analytics for Enhanced Insights

Visual analytics is transforming the way businesses interact with their data, an important development in the latest trends in supply chain automation and integration. By representing data in an easily digestible visual format, such as dashboards and heat maps, decision-makers can quickly grasp complex information. This visual representation aids in identifying trends, patterns, and anomalies, facilitating quicker and more effective decision-making.

In summary, advanced analytics plays a crucial role in the latest trends in supply chain automation and integration. By providing comprehensive, predictive, and visual insights, it empowers businesses to make smarter, data-driven decisions. This capability is essential for navigating the complexities of modern supply chains and maintaining a competitive edge.

Seamless Integration with ERP and CRM Systems

Seamless integration of Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems is a defining characteristic of the latest trends in supply chain automation and integration. This integration is crucial for creating cohesive and efficient business processes.

Enhancing Customer Relationships with CRM Integration

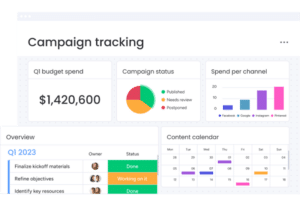

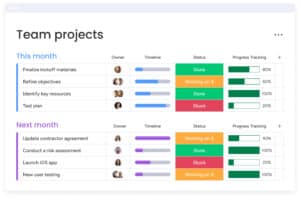

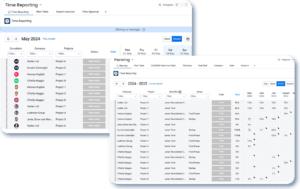

CRM systems play a pivotal role in the latest trends in supply chain automation and integration by enhancing customer relationship management. Integrating CRM systems with supply chain operations ensures that customer data and insights are readily available, enabling businesses to make customer-centric decisions. This integration leads to improved customer service, higher satisfaction levels, and increased loyalty. A highly integration-friendly CRM system that’d work perfectly for this scenario is monday.com sales CRM. Its customizability and integration capabilities make it stand out from its competitors.

Streamlining Processes with ERP Systems

ERP systems are the backbone of effective supply chain management. By providing a unified view of all business operations, ERP systems help streamline processes, reduce redundancies, and optimise resource allocation. This integration facilitates better planning, forecasting, and coordination across the supply chain.

In conclusion, the seamless integration of ERP and CRM systems is a cornerstone of the latest trends in supply chain automation and integration. It not only enhances internal efficiencies but also improves customer engagement and satisfaction. The comprehensive integration of these systems is imperative for businesses looking to thrive in today’s dynamic and interconnected market.

Conclusion: Embracing the Future of Supply Chain Automation

As we have explored throughout this article, the latest trends in supply chain automation and integration are not just fleeting changes; they are significant shifts that are reshaping how businesses manage their supply chains. From the adoption of AI and ML to the integration of IoT, blockchain, advanced analytics, and seamless ERP and CRM systems, these trends are setting the stage for a more efficient, transparent, and resilient future.

The Strategic Advantage of New Technologies

The integration of these technologies offers businesses a strategic advantage. By embracing the latest trends in supply chain automation and integration, companies can improve operational efficiency, reduce costs, enhance customer satisfaction, and stay ahead in a competitive market.

Preparing for a Connected and Automated Future

It’s crucial for businesses to not only understand these trends but also actively prepare to implement them. The future of supply chain management is undeniably connected and automated. Companies that invest in these technologies now will be better positioned to navigate the challenges and opportunities of tomorrow’s market.

Leverage monday.com for Enhanced CRM and Project Management

One of the key tools that can help in this transition is monday.com. With its robust sales CRM and project management capabilities, monday.com is an ideal platform for companies looking to streamline their operations and enhance efficiency. Whether it’s managing customer relationships, overseeing complex projects, or integrating various aspects of your supply chain, monday.com provides a versatile, user-friendly solution.

If you’re interested in leveraging the capabilities of monday.com for your business, we’re here to help. Reach out to us for a free consultation through the button below. Our team of experts will guide you through the possibilities and help you tailor a solution that fits your unique business needs. Don’t miss the opportunity to transform your supply chain management with one of the leading tools in the industry. Contact us today and take the first step towards embracing the future of supply chain automation.

If you enjoyed this blog post, make sure to sign up for our monthly newsletter below. Stay in the loop regarding all things business automation and efficiency!